Special gearbox manufacturing

GT- rotation, development and batch production of a special gearbox

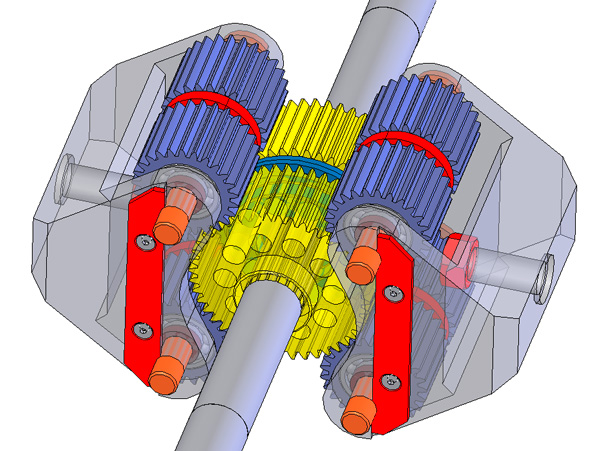

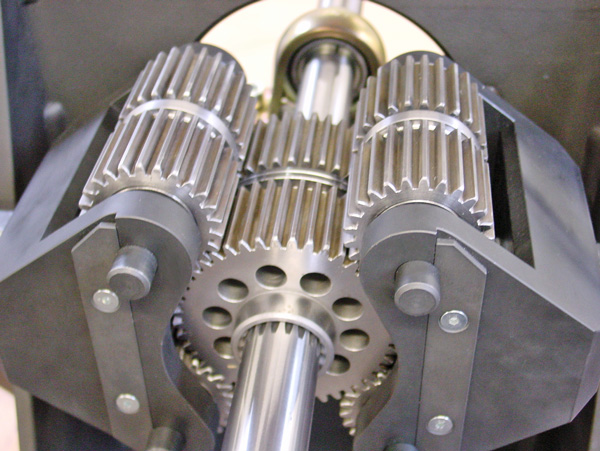

Initial situation: A drive provided by the client, consisted of the combination of a planetary gear, a bevel gear, a spur gear and a highly dynamic separate servo motor into individual casings that were flanged together. Due it’s construction, this drive concept had a low torsional stiffness and a substantial backlash, which proved unsuitable for the operation of the regulated servo motors.

Task: The development of a compact, torsionally stiff drive with possibly less backlash and a high power density.

Solution: The integration of a highly dynamic -frameless- servo motor and a two-stage, adjustable total spur gear takes place in a common cast steel housing with a manually switchable brake. Through this design principle, an enormous torsional rigidity was achieved with a backlash of <= 0.005 mm. Thus an achievement of over 50% time saving with the dynamic positioning of large masses.

Call

Call Route

Route Mail

Mail