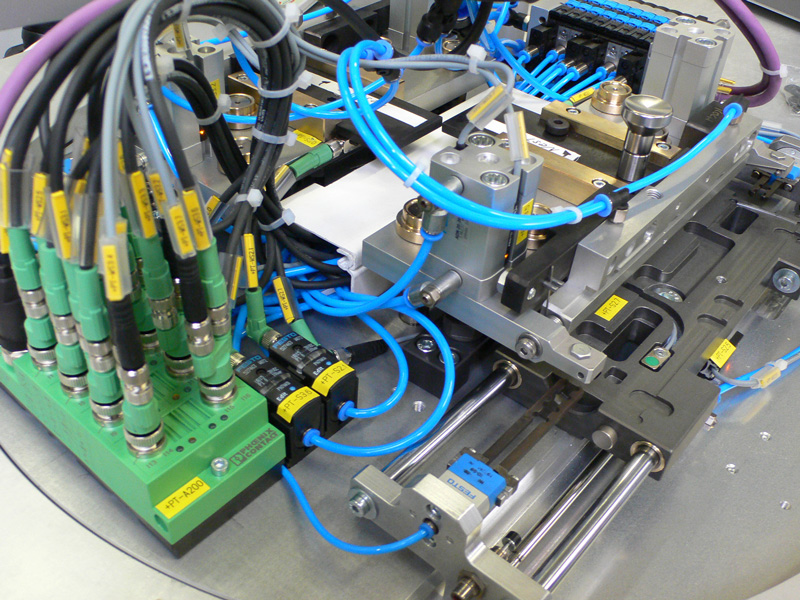

Automation engineering

With new production or manufacturing philosophies being put into practice, the industry is demanding an increasingly high degree of automation.

Former manual workplaces have to be partly or fully automated. Among other things this requires the precise observation of

- quantities

- output quantity

- clock frequency

- operational safety

- process capability

- process integration

Depending on customer requirements, we take automation ideas over, or, drawing from our experience, we develop new solution concepts to optimise the production or manufacturing processes.

Our core competence here lies in taking over the complete automation process

- analysis of actual situation

- concept development

- planning / development (mechanics / electrics / control)

- realisation (mechanical hardware, electrical hardware)

- commissioning

- schooling

A cost-effective production and manufacture is at present very important for Germany as business location. In order to achieve this in line with the market requirements, it is necessary to automate production and manufacturing processes.

Our customers from highly diverse fields give us the task to automate an existing process. Either we are given precise specifications how the process is to be automated, or we take the actual condition and develop a solution ourselves how the process can be completely represented, in order to fulfil specifications like clock cycles, quality, individual test steps, etc.

Call

Call Route

Route Mail

Mail